Fully automatic conversion for tension strut variants

The machines described here represent our broadly diversified competence. Various solutions for diverse workpieces with different degrees of automation and cycle times have been implemented in these examples, with the majority of the tension bracing struts installed in vehicles being rod-shaped elements.

They transmit the drive and braking forces arising on the moving parts of the chassis (e.g., axles) to the chassis.

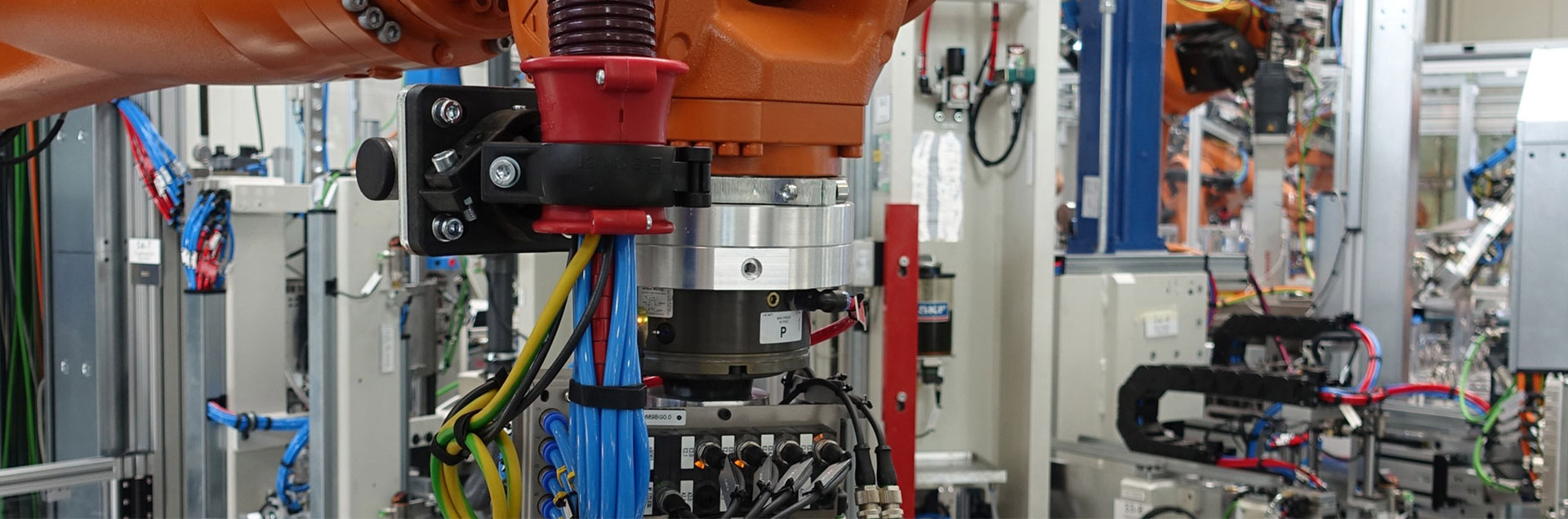

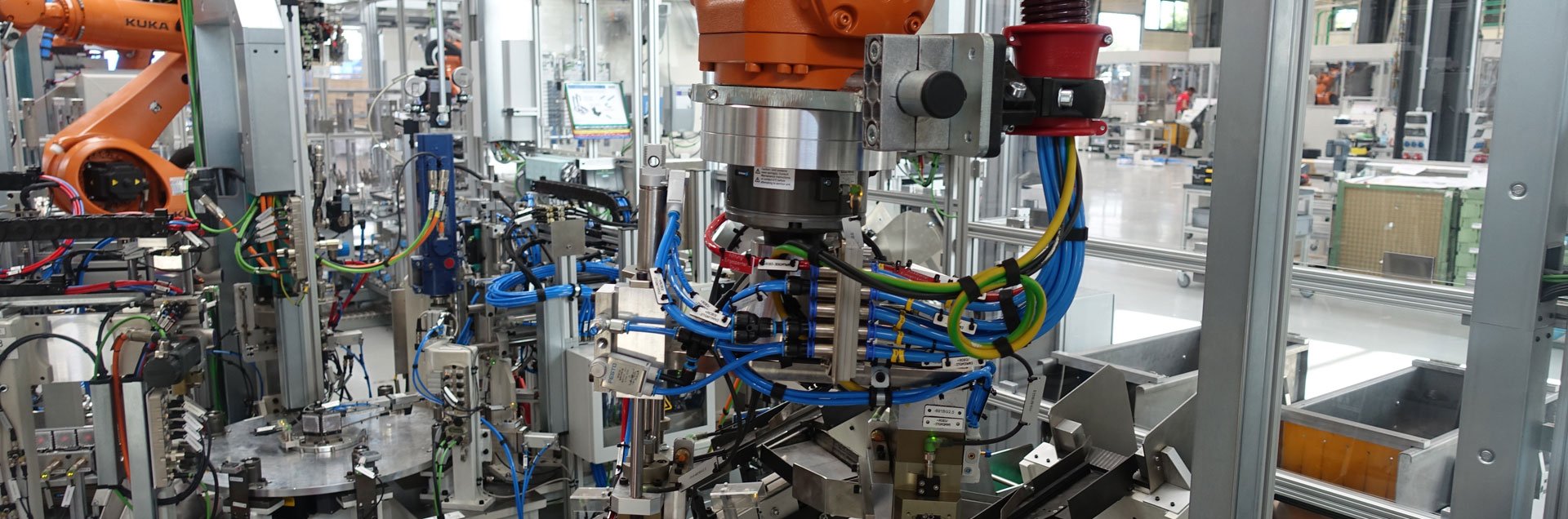

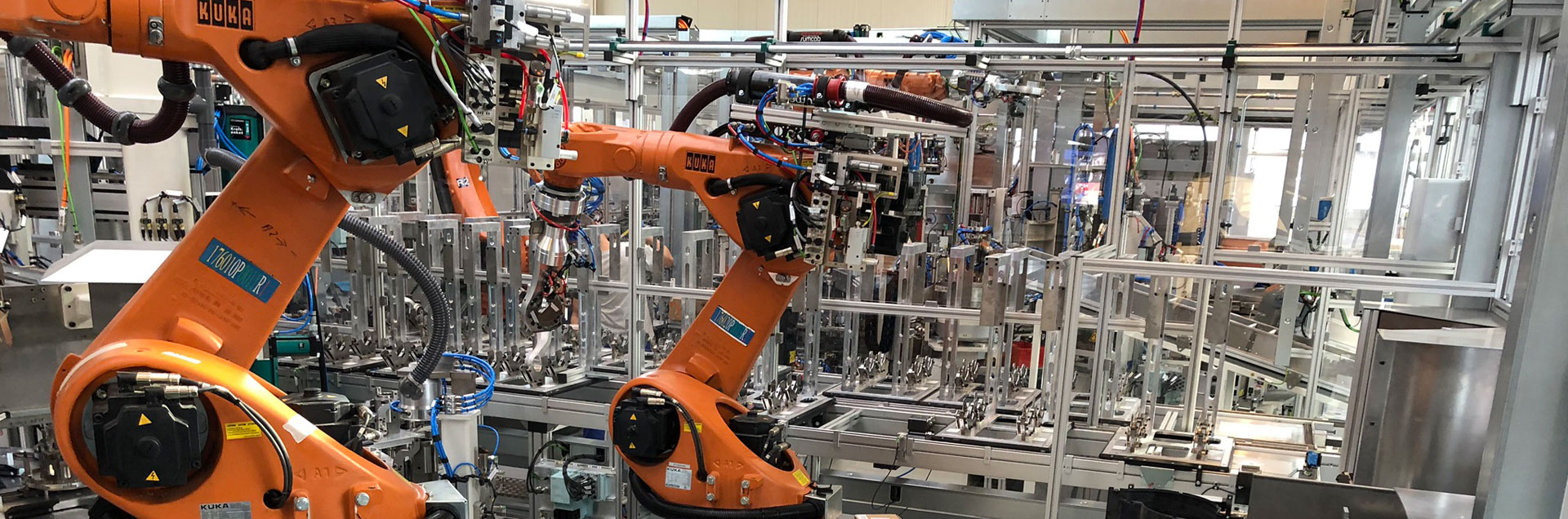

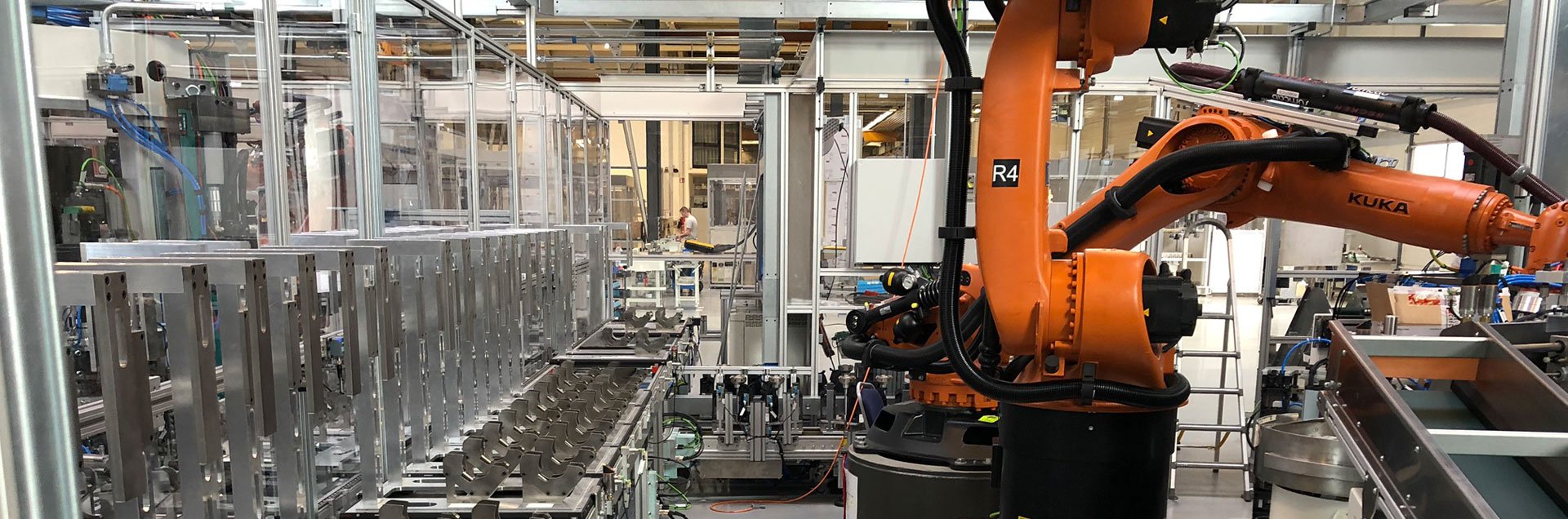

Over an area of 17.4 x 11.5 m, 20 different tension bracing strut types (40 variants in total) are assembled in approximately 18 process steps within a cycle time of 10 seconds. The main components of this assembly system are 3 rotary indexing units and 7 robots for parts handling. The conversion from one type of tension bracing strut to another is fully automatic and a manual emergency loading strategy is provided.

For each workpiece, 34 pieces of quality data (time stamp, status, measured value, type) are transferred via an interface to a quality database.

Due to the variety of parts and complex geometries, the workpiece carriers are an in-house development.

- Number of assembled components:7

- Variant variety/complexity:20 (40 variants)

- Operation cycle time:10 s -> 7,900 workpieces a day in 3-shift operation

- Number of processes:18

- Required personnel:Fully automatic conversion, manual removal of the assembled parts (requirement specification)