High output with high flexibility

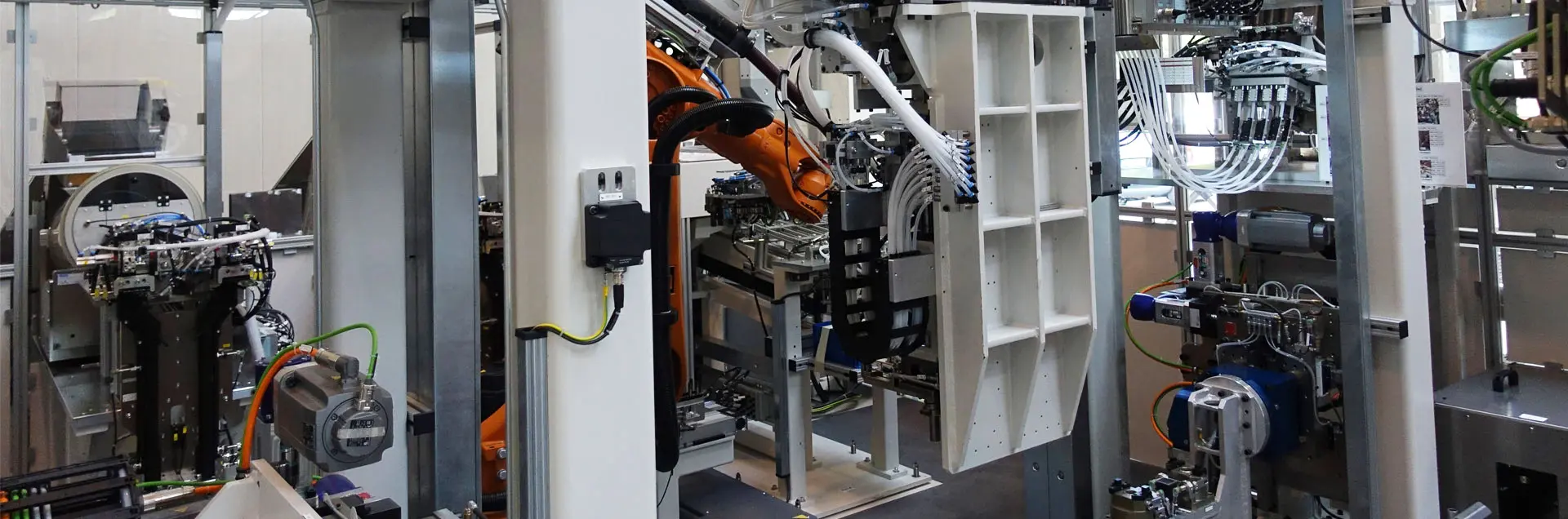

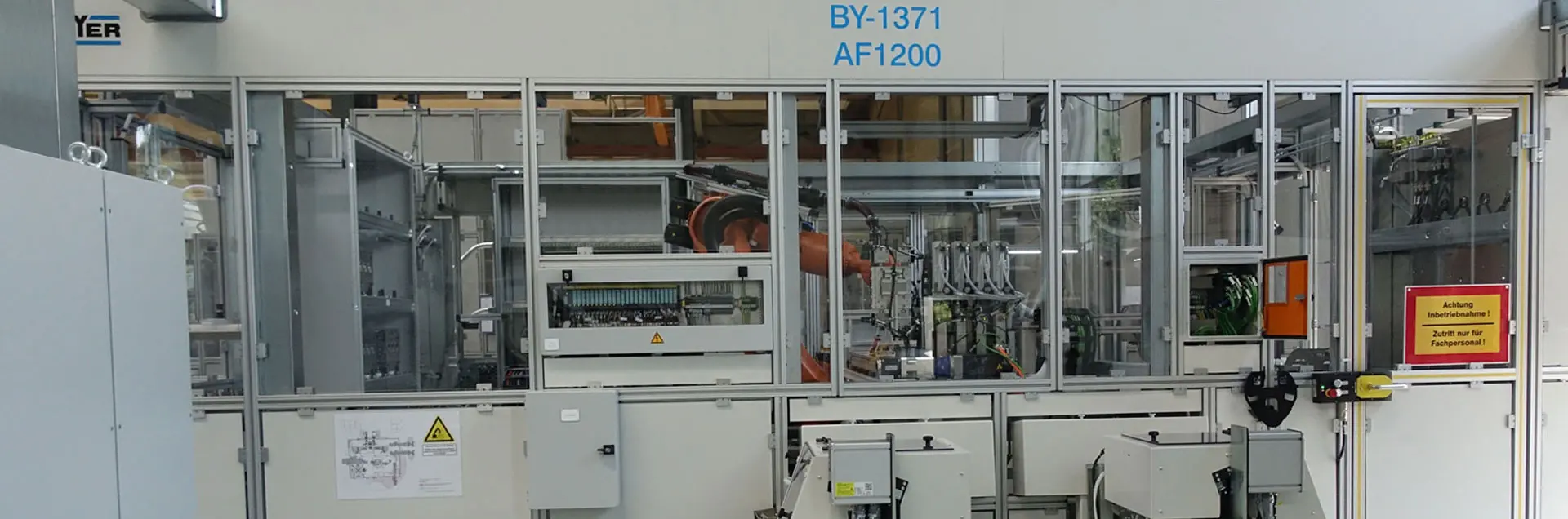

With an hourly rate from 5,000 to 25,000 add-on parts are assembled and tested in up to 20 different variant configurations.

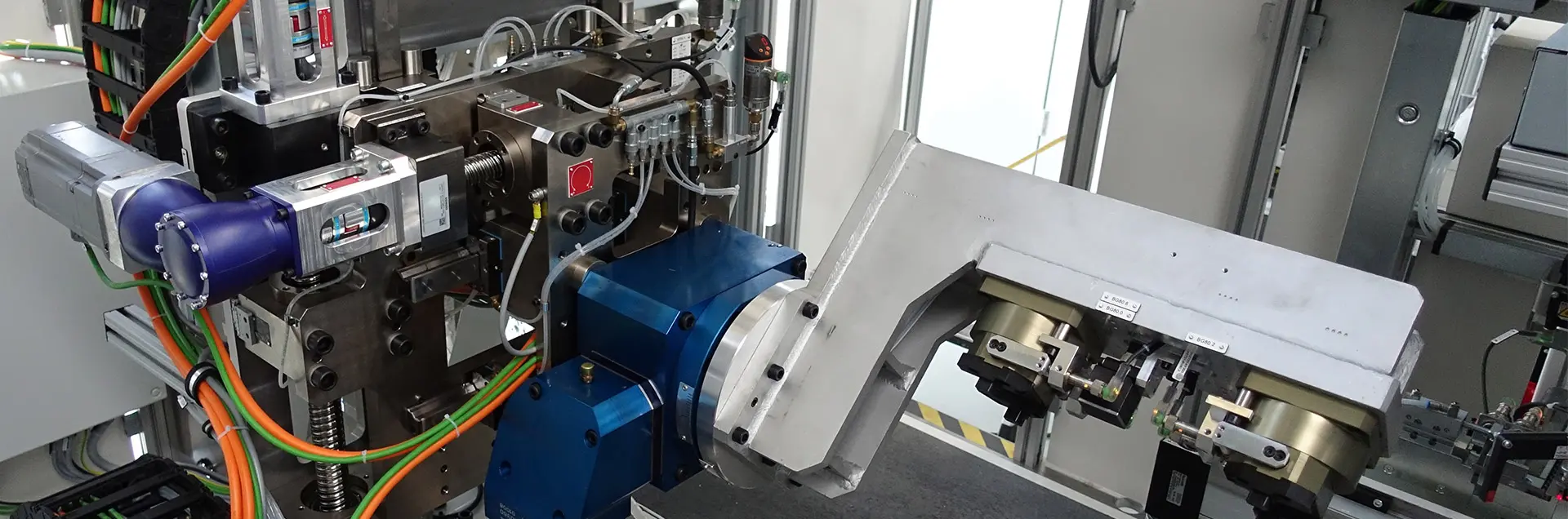

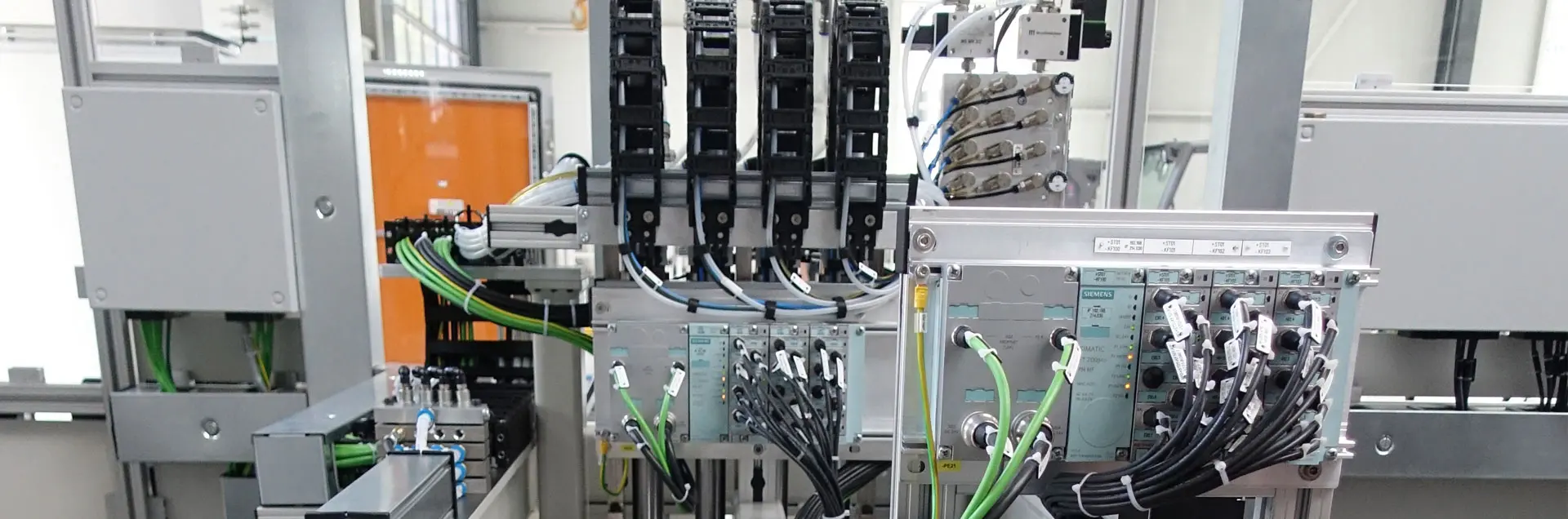

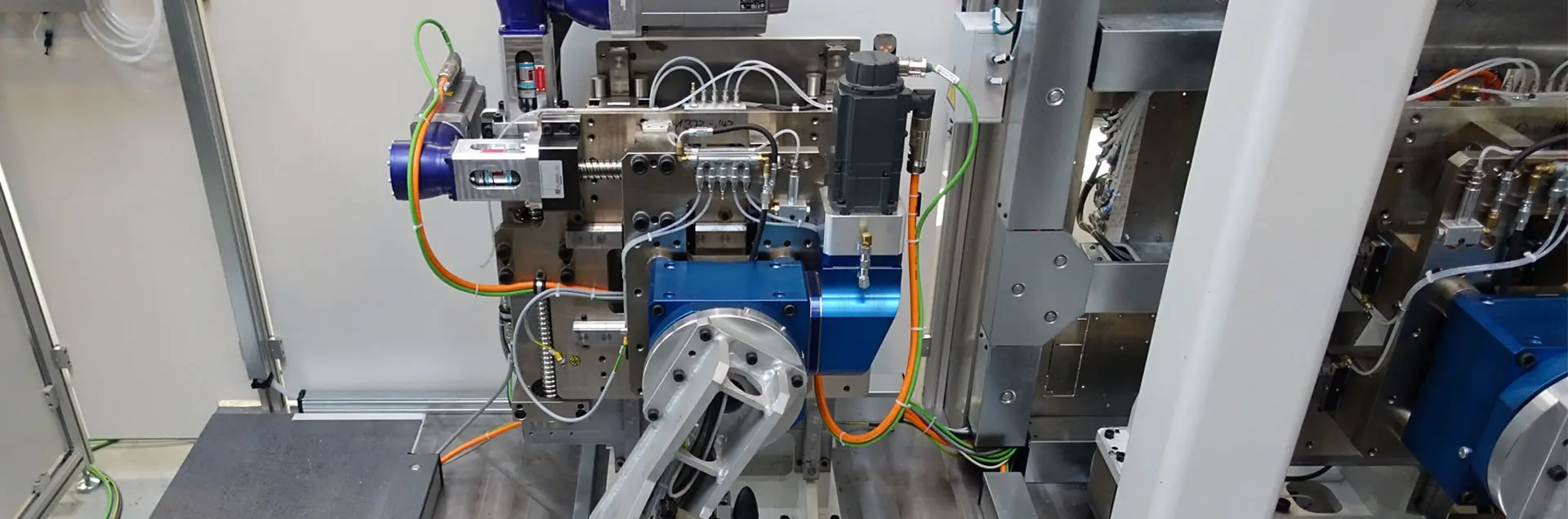

In the process, we combine feeders, untanglers, blowers, press-in units, lasers and gantry or 6-axis robots to create an ideal solution. The diameter, length, colour and depth of the feed parts are checked before and after assembly to ensure the best possible product quality.

The machine bed concept for fast assembly and disassembly enables rapid integration into the customer's production environment and reduces downtimes of neighbouring machines. We plan retrofitting options and provide for future variants and/or increases in quantity from the very beginning.

- Number of assembled components:168

- Variety of types/complexity:20 Varianten

- Workpiece transport:Roller conveyor, alternatively, workpiece carrier systems

- Cycle time:28 s -> 2,400 workpieces a day in three-shift operation

- Number of processes:8 – 12

- Required personnel:Fully automatic changeover and manual removal of the completely assembled parts (customer’s requirement specification)

- Checked parameters (characteristics):Correct assembly of valve wedges and valve spring retainers using a triangulation laser