Internal and external tests with special measuring technology

Mobile leak test system for the fuel cell in which the stack is the electrochemical centre of the fuel cell drive technology. It consists of many cells connected in series, which carry out the energy conversion. The cells in turn consist of a cathode, an anode, and an intermediate solid or liquid separating layer, the so-called electrolyte.

The housing around the stack protects it from external influences. It fixes the components of the stack in its interior to ensure trouble-free operation.

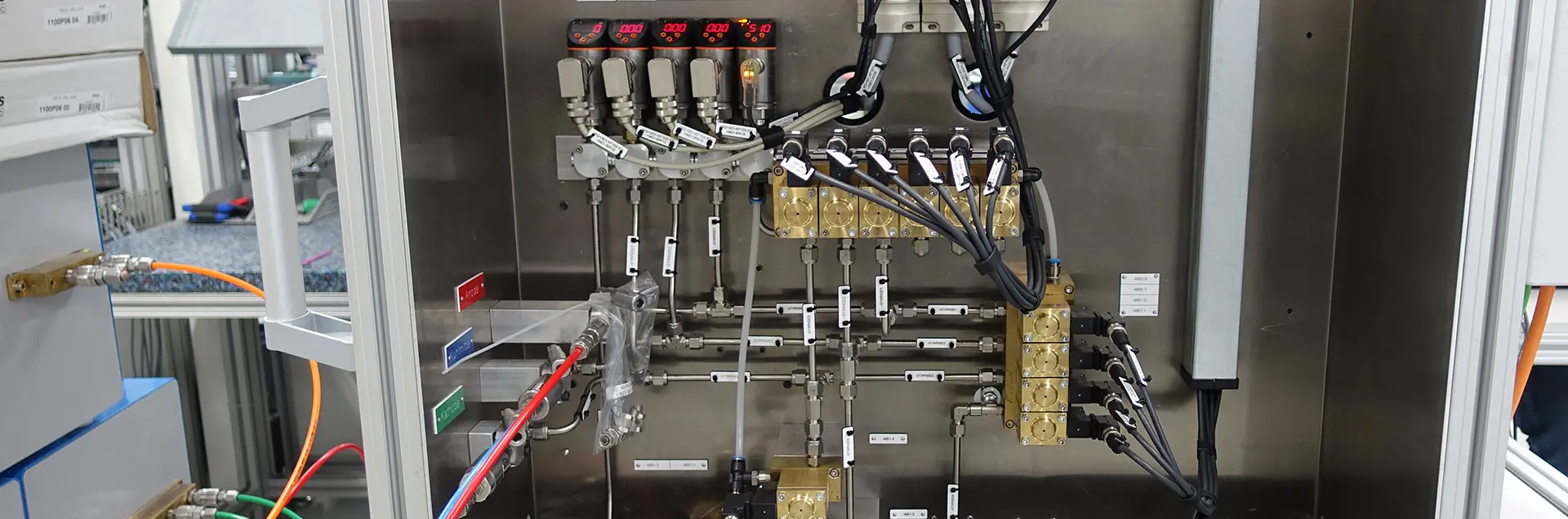

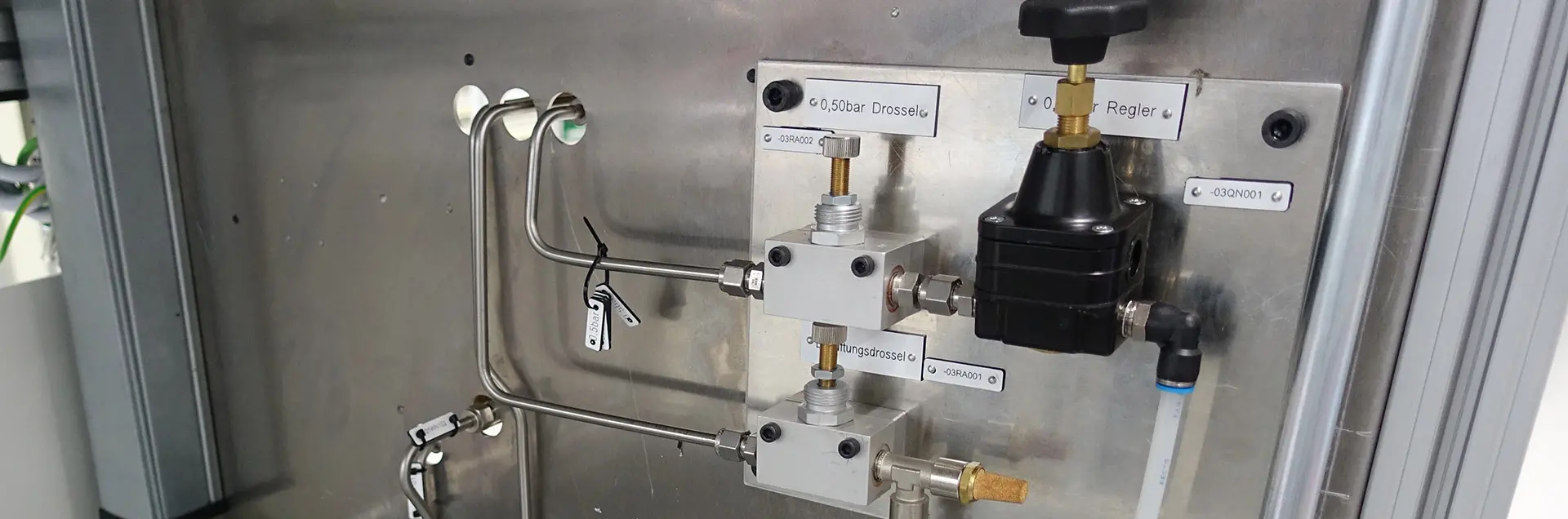

In a pilot line for fuel cell assembly, the leak tightness of the stack is tested with air in a semi-automatic workstation. The tests are carried out fully automatically according to selection by the higher-level system. After a rough leak test, the test system measures the leak tightness of all stack chambers to the outside (external test) and, in a second step, the leak tightness of the chambers to each other (internal test), for which a specially-developed measuring technique is applied.

After an assembly process has been carried out on the stack, a further external test is performed.

In a second step, the stack housing assembly takes place. The leak tightness of the housing to the outside is then also tested. The test system forwards the measurement results in conjunction with the workpiece number to the higher-level system.