Integrable process in automatic solutions

Friction stir welding is particularly suitable for cost-effective joining of non-ferrous metals with low melt temperatures and mixed joints. Even materials that are difficult to weld or atypical, such as aluminium, magnesium, copper, titanium or steel can be joined together.

In friction stir welding, a rotating pin is guided between the contact surfaces of the joining partners. The friction between the tool shoulder and the joining partners heats the material under the shoulder to just below the melting point. This rise in temperature results in a reduction in strength, which plasticises the material and allows the joining zone to be mixed. The result is a high-strength microstructure.

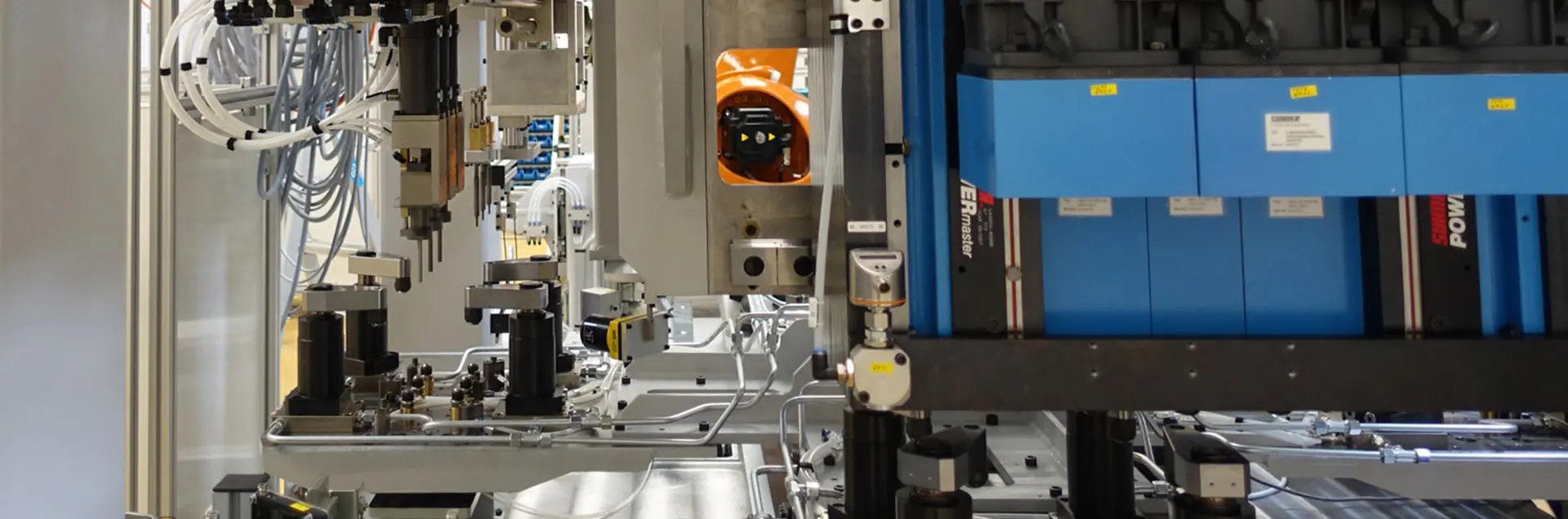

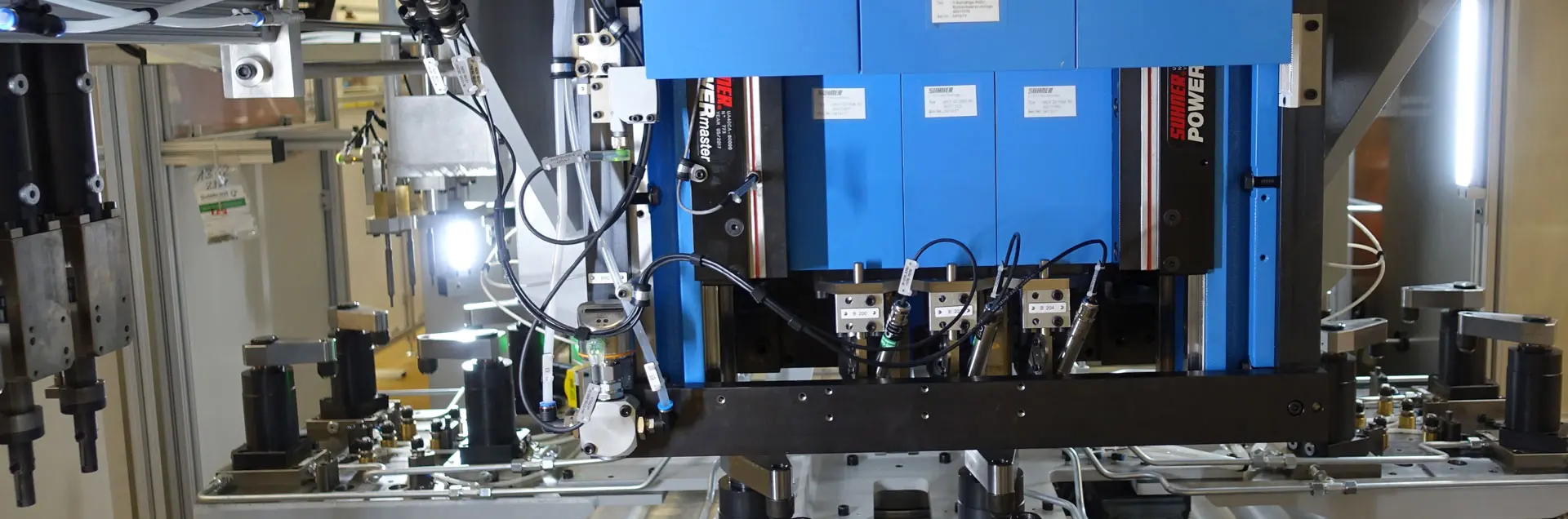

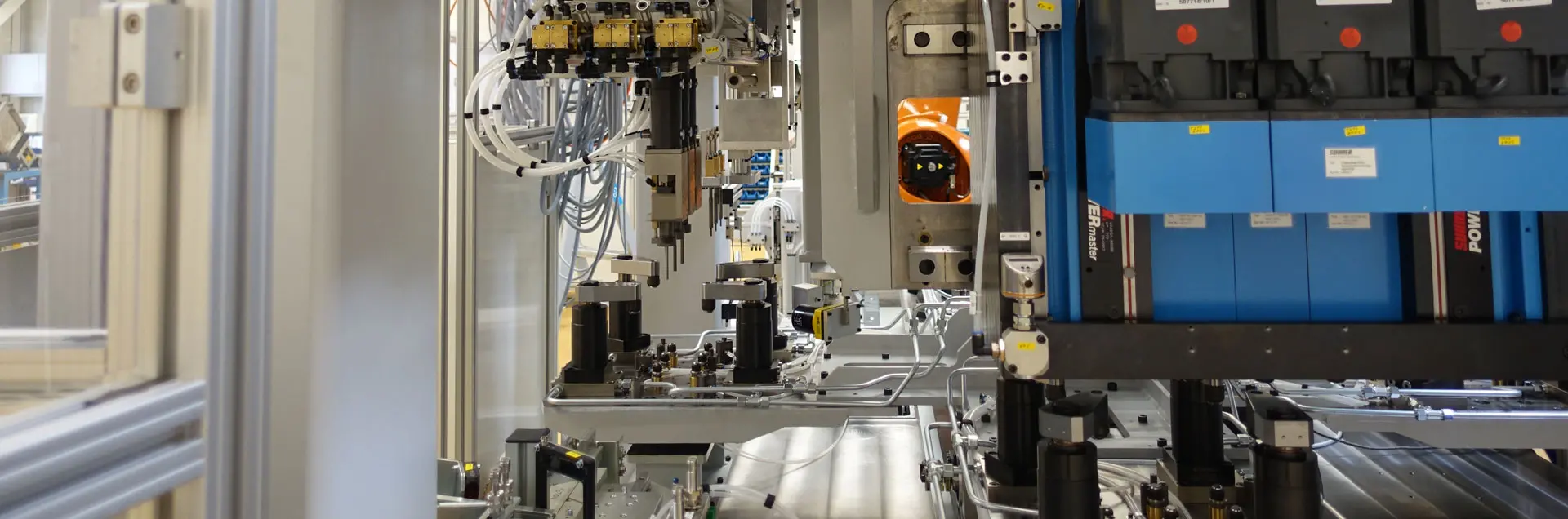

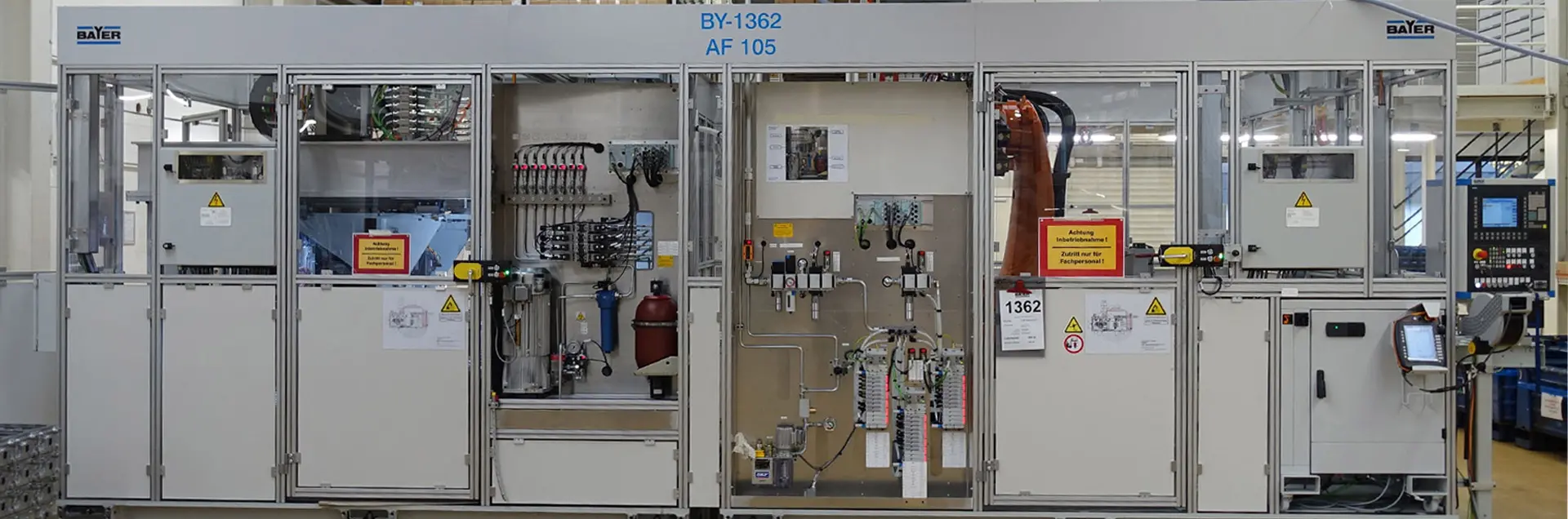

This process can be integrated into one of our automated solutions. During the entire welding process, the specified values for speed, feed, axial force progression, torque and Z-axis control position correction value can be adjusted at each spindle and the process data can be saved with the date and time.

An application example is the welding of aluminium plugs into a cylinder head in order to seal cavities formed after the casting process.

Friction stir welding and assembly machine