Further development

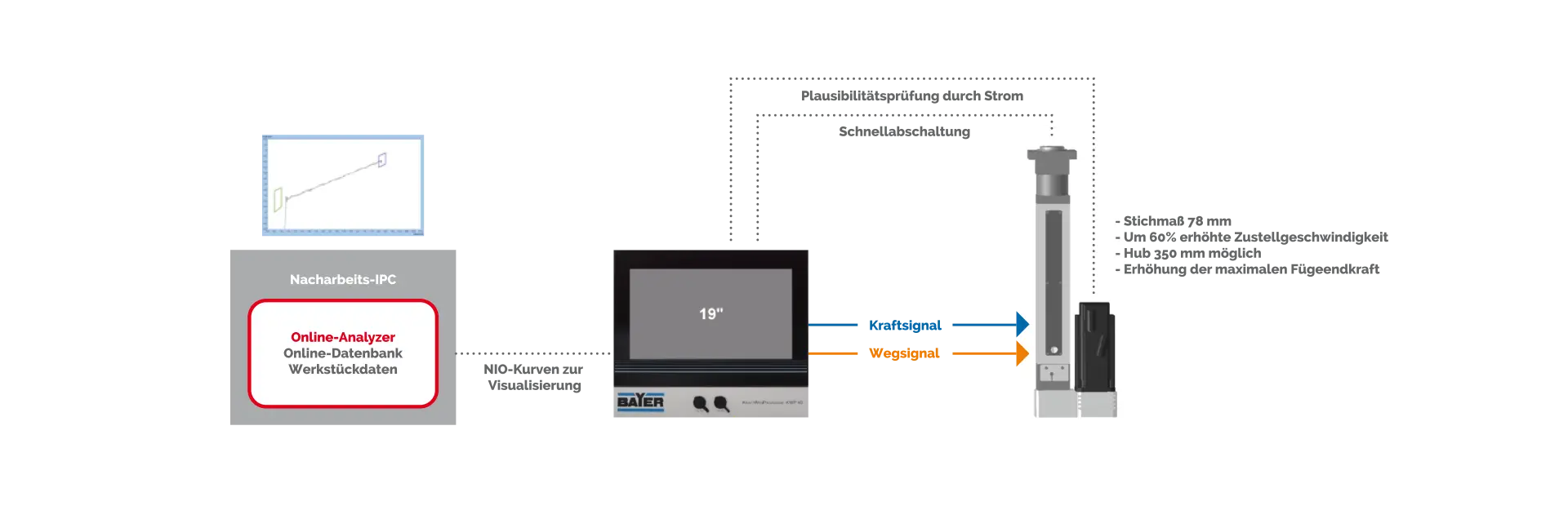

The vision for the further development of the BAYER press-in system was to standardise the electrical hardware by following the SIEMENS standard and to integrate the possibilities offered by the control technology (rapid switch-off, plausibility check by the current) and IT (database, visualisation, evaluation by superimposing curves).

On the mechanical/kinematic level, the feed speed of the press-in unit was increased by approx. 60%, as well as the maximum pressing-in force (here depending on the load case). The distance between the centerlines of two press-in units is 78 mm matching the gauge for boreholes of cylinder heads by pressing-in valve seat rings and valve guides.