High flexibility, thanks to a wide variety

Drive shafts consist of fixed and constant velocity joints, bellows, retaining rings and hose clamps. They are required in numerous types and combinations for a large number of different engines, gearboxes and suspensions.

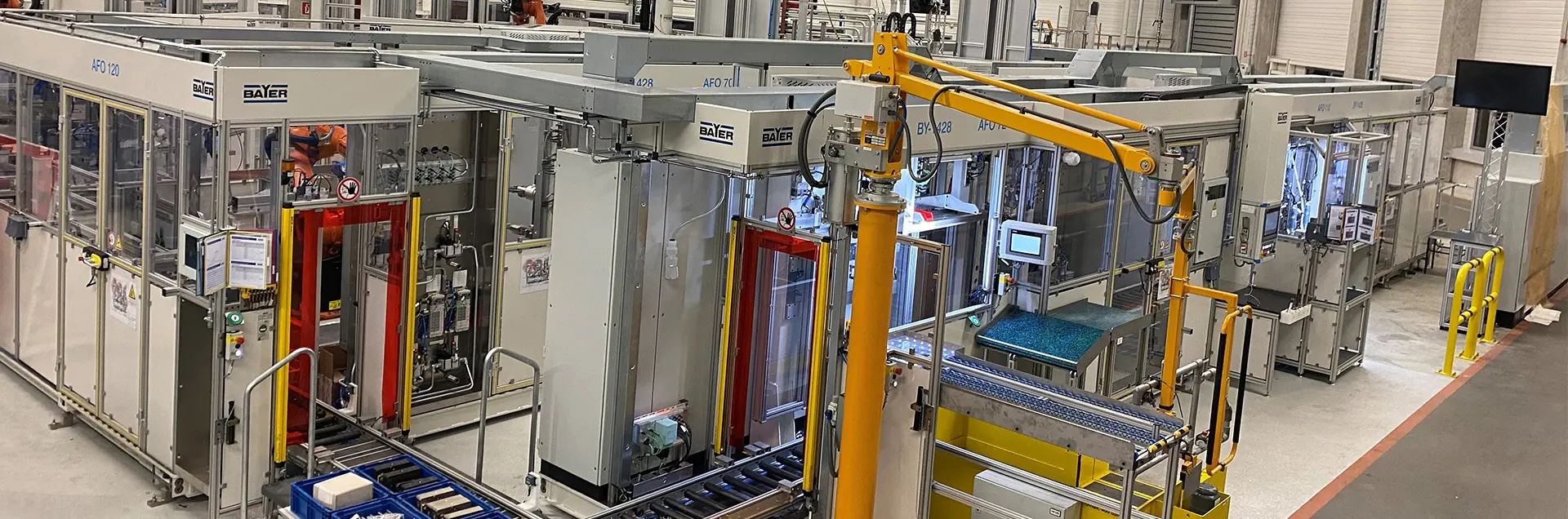

Producing these components automatically in an assembly machine is a challenging task that we will gladly undertake. We will develop your machine according to your needs and in line with your current requirements. In the process, we work with foresight to take future issues into consideration before they arise. Ergonomics and maximum flexibility, coupled with a high output are our top priorities. This is achieved with circulation belts, rotary tables and indexing systems.

Together with quality assurance testing and lubrication tasks, the feeding, pressing-in and marking processes are performed in a fine-tuned workflow with ergonomic workstations and efficient robots.

The complete assembly of up to 3,000 shafts per day in one machine is a feasible challenge for us. Let us know what your shaft should looks like and we will find a future-proof solution.

- Number of assembled components:Fixed joint (many types), tripod housing, tripod star support (many types), bellows (many types), hose clips (many types), retaining rings (many types)

- Variety of types/complexity:4

- Workpiece transport:Workpiece with workpiece carrier on pallet circulation conveyor

- Cycle time:≤ 25 s

- Number of processes:Pre-assembly, assembly of fixed joint and tripod star support, assembly of bellows + 2 small hose clips, assembly of retaining ring on wheel side, preliminary inspection, greasing and lubrication of fixed joint and tripod housing, assembly of retaining ring for tripod housing

- Required personnel:2 employees; 1 plant operator

- Checked parameters (characteristics):7 cameras and 3 scales

- Control technology and data transmission:3 PLCs, 7 robots; 1 control computer